DaySpring has a longstanding partnership with 1st Employment to provide high quality people to meet our labor requirements. This relationship includes a shared commitment to provide a safe work environment for all employees, through the use of good common sense, established safety procedures and training. 1st Employment has provided you with basic training for Lock Out / Tag Out & Accident Prevention Signs and Tags. In addition, DaySpring would like to you to review the following.

What is LO/TO? A specific work safety procedure or practice that safeguards employees from the unexpected powering or startup of machinery and equipment, or the release of hazardous energy during service or maintenance activities.

We have two types of employees in our LO/TO program.

- Authorized – any employee who can lock and or tag out a piece of equipment to perform repairs or maintenance.

- Affected & Other– any employee who may use the machinery for its intended purpose and or work in an area where LO/TO by authorized employees could take place.

If any of the following conditions exist, LO/TO must be utilized. Do not attempt to use the machinery. Contact your immediate supervisor for assistance.

- Machine guards must be removed or bypassed

- Personnel must place any part of their body in contact with any moving part (such as the point-of-operation) or inside of machinery/equipment.

- Personnel must place any part of their body within a danger zone within a machine’s operating cycle.

The following is a list of machines in the area you will work, that are included in our LO/TO program.

|

Conveyor Line

|

Pallet Wrapper

|

|

Fair Hope Box Erector

|

Pillow Pack

|

|

3M Tape Machine

|

Lift Table

|

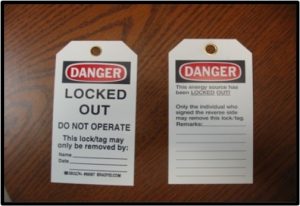

Below are the isolation devices used to prevent the unexpected startup of equipment and warning tags which alert employees that the machinery is out of service and should not be operated.

Lock – prevent unexpected start up

Tags – serve as warning only

As an affected employee, you should be able to recognize these items. Anytime a machine has either present, our policy is that no one should attempt to operate the machine, other than authorized personnel.

Following these simple guidelines will ensure your safety while machines are being repaired or serviced.

OSHA Regulation (29 CFR 1910.45) (Specifications for Accident Prevention signs & Tags) requires that as an employer, DaySpring make you aware of potential workplace hazards and the type of sign and or tag that will be used to inform employees about the hazard.

Accident Prevention: Signs & Tags can be used in a wide variety of applications to help prevent accidents.

- Barricades, Signs, Tags

- Posted where hazard is

- Instructions to follow to stay safe

In addition, it is important that you understand the level of severity presented by each hazard, which is communicated by the color and wording on the sign and or tag. Please review the list below.

RED, immediate threat to life, precaution is necessary.

- WARNING: ORANGE, mid-level hazard/ severity or potential.

- CAUTION: YELLOW, potential hazard, use proper precautions, less severe injury.

- SAFETY INSTRUCTION SIGNS: BLUE or GREEN, general instructions and safety measures.

- BIOHAZARD: orange-red, bright orange, actual or potential presence of biological hazards.